Advised by Docent Silvan Oesterle

USI Accademia di Architettura Mendrisio

Abstract

Imminent consequences of human climate alterations are substantially attributable to the construction industry. In light of the necessary paradigm shift in the sector, the reuse of structural elements is likely one of the most promising paths to sustainable construction. Current structural design standards creating load-bearing systems that age prematurely and require the destruction of all components must be rethought to move towards a circular construction economy. Looking at current research to identify the possible implications and hurdles of implementing such strategies on a large scale, we identify that markets for available parts could be created in the form of networked reclaimed component libraries, with both warehouse-stored scavenged elements and parts from buildings yet to be deconstructed, acting as material banks. Algorithmic tools could reduce the friction in selecting the right pieces in this stock-constrained design process involving large datasets, potentially reducing transport costs, stimulating regional economies, and better preserving historical significance.

Keywords

- Sustainable Construction

- Circular Economy

- Markets for Reused Elements

- Buildings as Material Banks

- Stock-Constrained Design

- Algorithmic Structural Optimisation

I - Assumptions

1. The construction industry is responsible for a considerable share of global greenhouse gas emissions (GHG)

Most contemporary greenhouse gas (GHG) emissions are caused as a byproduct of the production of cement and steel.1 Cement is the largest manufactured product on Earth by mass and the second most widely-used substance in the world after water. Embodied carbon in buildings, such as CO2 emissions associated with the manufacture of building components, construction, renovation, and end-of-life, accounts for 11% of the total annual energy- and process-related CO2 emissions worldwide. The current global annual demand for steel and cement is an astonishing 2.5 gigatons, which is double the amount from 2000.2 Paradoxically, cement-based concrete possesses very limited end-of-life potential most of it being at the present wasted and landfilled. (See chapter I.4) Structural steel is primarily produced in furnaces that generate large quantities of carbon dioxide. However, steel structures are easily dismantlable and composed of relatively long-lasting standardized sections which large open-ended life-cycle possibilities.

Can construction-related emissions be reduced?

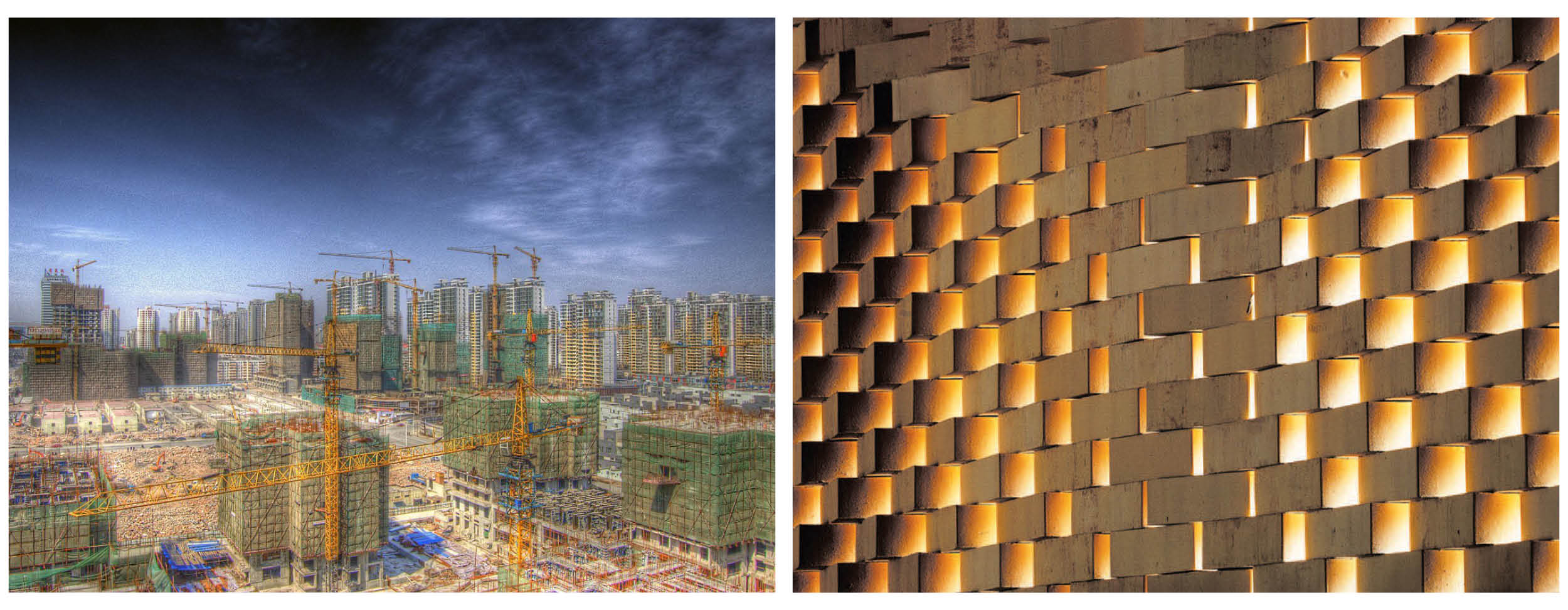

fig.1

a.Tianjin

Construction Site, Jakob Montrasio b.Winery

Gantenbeim, Gramazio Kohler.

fig.1

a.Tianjin

Construction Site, Jakob Montrasio b.Winery

Gantenbeim, Gramazio Kohler.

2. The resurgence of material and energy scarcity is looming

As theorized in 1971 by Nicholas Georgescu-Roegen in the Entropic Law and the Economic Process, and in 1979 by Herman Daly in his theory on the energy flows in the physical universe, entropy defines the degree of disorder of a system which reflects the amount of energy unavailable to do work.3 As such, entropy can be viewed as a measure of a system’s used-up energy. The Second Law of Thermodynamics states that the entropy of a system always increases and never decreases. As Earth’s resources and energy are finite, it has been argued that the entropy law imposes an absolute resource scarcity that cannot be overcome with technological change, exploration, or substitution.4 Indeed, they describe the passage from a pre-carbon to a carbon economy as the moment when humans started to depend on free energy from within the Earth’s crust instead of relying on transformed energy from the sun. This shift was made from the low-entropy input from the solar to the terrestrial source.5

This theory is further corroborated by Elisa Iturbe and conceptualized into the term Carbon Form. This term defines urban and societal arrangements that mostly depend on fossil resources. In these arrangements, urban and architectural spaces play an active role as they guide modes of consumption toward carbon-biased means. Iturbe gives the following examples of types of Carbon Form, defining their existence not only in urban and architectural typologies, but also in the spaces and objects of our everyday lives: fast food chains, roadside motels, a delivery truck full of bottled water idling on an asphalt street, the appliance section of a department store, military installations, the internet, Las Vegas, natural gas pipelines, and the Indy 500.6

Since the dawn of the industrial revolution, the physical limits of our world have been recognized, warning of the consequences of over-exploitation of common resources for the global economy and environment.7 The Limits to Growth reports published by the Club of Rome since the 1950s8 9 have continued to warn that, without substantial changes to resource consumption, rapid and uncontrollable decreases in population and industrial capacity would be inevitable.10 Given the finite nature of resources and the framework provided by the aforementioned Entropic Law and Carbon Form theories, it is apparent that the exploitation of natural resources needs to be re-evaluated and reorganized to ensure sustainable and responsible use. Elinor Ostrom’s Governing the Commons11 explores potential pathways, focusing on how a decentralized, participatory market may regulate the use of common-pool resources and guarantee fair resource access.

Can we reimagine the distribution of material and energy resources?

3. The Age of Computational Abundance

In the age of data abundance, information that used to be rare and expensive is now ubiquitous and cheap, which also applies to computational power. Mario Carpo coined the term ‘Second Digital Turn’ to describe the reversal enabled by the progress of processors and the exponentially increasing availability of data. Instead of relying on mathematical description and human computation, retrieval of precedents has replaced calculus, and a shift from form-making to form-finding has occurred. Computers are now described as self-organizing systems and can behave in unpredictable ways that are often counterintuitive.12 In all areas of life and science, the traditional cause-and-effect, the deterministic approach has been replaced by a new post-scientific method based on probabilism, statistics, heuristics, and holistic processes.13 Increasingly, we are no longer calculating, but searching and retrieving,14 and we are better equipped to handle complex systems as a whole rather than the simpler logic of their predictable components.15

In the construction field, BIM (Building Information Modelling) and IPD (Integrated Project Delivery), similar to the Wikipedic style of many hands, allow objects to be created by many but no one in particular, with the objects, constantly evolving and open to interactive editing and participatory versioning.16 This allows for a degree of open-endedness and participation, the only difference being that a building must eventually be constructed. Designers can optimize a structural solution by simulating multiple trials and errors17, enabling them to identify the most suitable solution for their needs and explore design alternatives using an open-source, visual programming user interface on top of a widely-used BIM platform. This allows them to generate models of building design options, assess the environmental performance of the models through cloud-based simulation, and ultimately find the most appropriate design alternatives18.

Can readily accessible data and computing power be a tool for constructing better buildings?

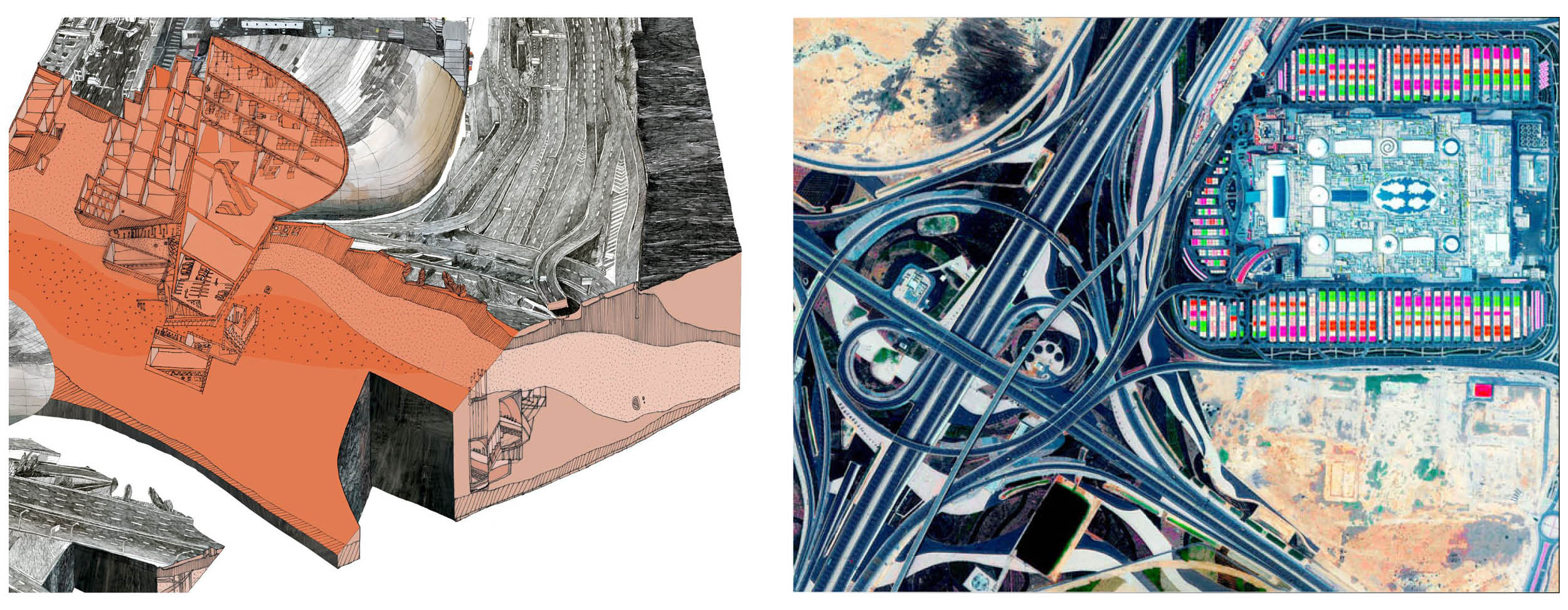

fig.2

a.Coupe!, Éva Le Roi. b.

Mall of Qatar at the Rawdat Rashed Interchange, Al Rayyan,

Qatar. Elisa Iturbe

fig.2

a.Coupe!, Éva Le Roi. b.

Mall of Qatar at the Rawdat Rashed Interchange, Al Rayyan,

Qatar. Elisa Iturbe

4. Current waste quantities present considerable potential for construction

For millennia, building tradition relied on common sense for the allocation of building materials. As every usable rock, brick or piece of timber was rare and precious, it was used and reused as long as possible. Paradoxically, in today’s cities, well-located land has orders of magnitude more value than the building standing on top of it. Buildings then become expandable, too often demolished and newly built, generating massive amounts of waste in the process.19 Generally categorized as Construction and Demolition Waste (CDW), it is the largest waste stream in the EU in terms of mass (374 million tonnes in the EU-28, in 2016, excluding excavated soil)20 and it accounts for more than one-third of all waste produced in the world. The latter is composed of a wide array of materials, including concrete, bricks, wood, glass, metals, and plastic which encompasses all the debris produced by the construction and demolition of buildings and infrastructure, as well as road planning and maintenance activities.21 Concurrently, regulations for disposal and landfilling become stricter, and landfilling sites are also becoming scarce.22 The case of Switzerland is particularly striking, as over 500 kilograms of construction waste are generated every second due to the demolition of buildings and the building industry is responsible for a staggering 84% of the country’s total waste production.23 This process is exacerbated in the case of the cross-border industrial symbiosis established between Switzerland and Italy, with Switzerland importing virgin aggregates from Italy for its industry, and Italy importing construction and demolition waste (CDW) from Switzerland for the environmental recovery of its quarries and to meet a growing demand for recycled construction materials.24

Can construction and demolition waste be transformed into valuable assets?

Thesis

Given these assumptions, as the necessity for a paradigm shift in the sector becomes apparent, the reuse of structural elements is likely one of the most promising paths to sustainable construction, taking inspiration from historical reuse practices and material efficiency principles paired with contemporary computational possibilities and data availability to achieve low-carbon low-waste building production.

II - A Circular Construction Economy through Digital Implementation

a. Sustainable Construction

Materials and processes are often described as having a certain energy content, and the embodied energy of the final product is the summation of the process energies attributable to its mass. This aims to give a sense of the energy intensity of a product but does not always reflect the environmental impact and carbon footprint. Strategies that save materials and reduce carbon impacts often require additional labor, which can sometimes outweigh the cost savings from using less material, thus resulting in a higher net cost for the more material and energy-efficient option. Analyzing the global impact of the construction sector, notions such as embodied energy, grey energy, and carbon footprint are often invoked. We define sustainable construction as a process that aims to minimize energy intensity as well as environmental impact and carbon footprint. Load-bearing systems such as foundations and structural elements are the biggest contributors to a building’s embodied energy.25 As such, structural decisions can greatly affect a project’s environmental impact,26 and this is where research shows the most potential contribution can be made.27

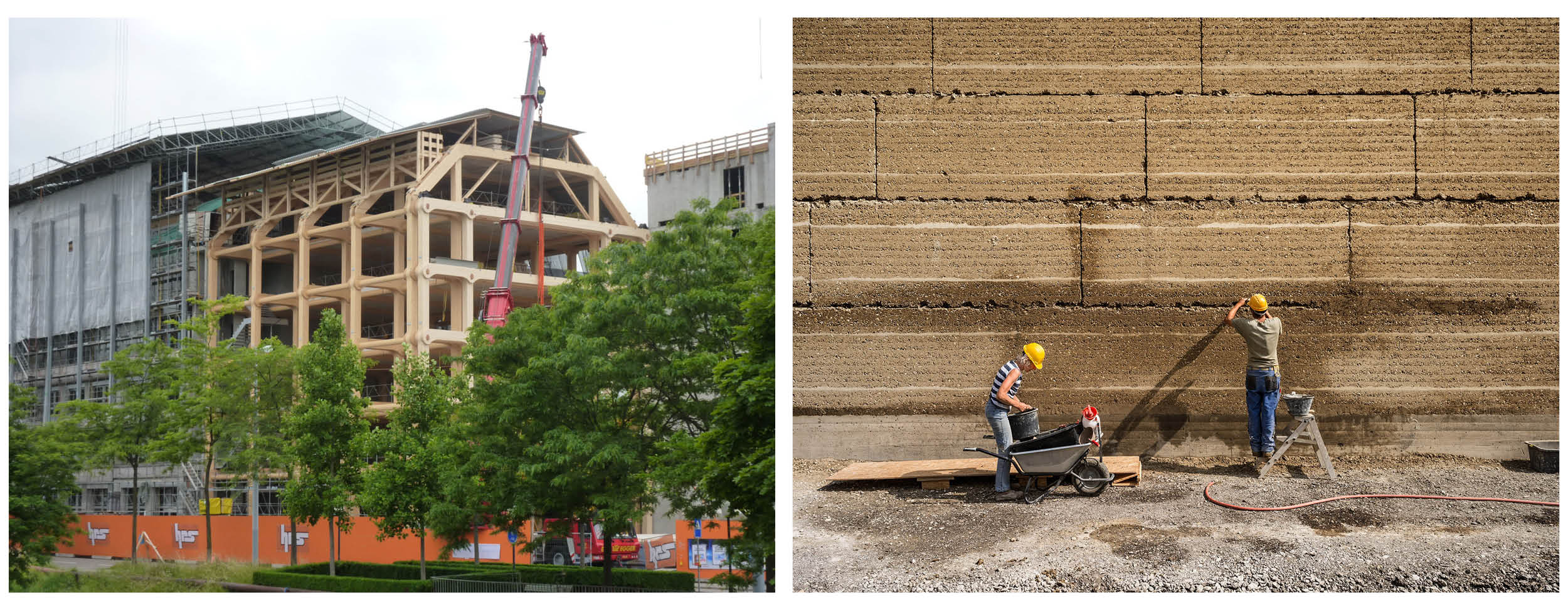

fig.3

a. Tamedia Office Building, Shigeru Ban.

b. Ricola Herbs Center, Herzog & De Meuron

advised by Martin Rauch.

fig.3

a. Tamedia Office Building, Shigeru Ban.

b. Ricola Herbs Center, Herzog & De Meuron

advised by Martin Rauch.

Three main strategies can be combined to build more sustainably: material choices, structural optimization, and the reuse of existing components.28 Firstly, the choice of materials is a powerful tool that designers can use to create more energy and carbon-efficient structures. The most widely used materials in current structures are concrete, steel, and timber. Material strategies should focus on reducing the use of the first two materials while increasing the use of the third and exploring alternative materials such as rammed earth. On the one hand, reducing the footprint of current mainstream building materials offers a short-to-medium-term path to reduce emissions. As concrete is the most widely used material on earth (see chapter I.1), reducing the utilization of cementitious materials has become a priority due to the sheer scale of their current usage. While this presents a challenge in transitioning to alternative methods, there is immense potential in the fact that even minor improvements to these processes can drastically reduce global emissions.29 Marginal gains in efficiency and reductions in emissions, as well as methods for producing less CO2-intensive concrete/cement30 and steel, can have exponentially cascading effects.31 On the other hand, sustainability can be sought by intensifying the use of inherently Carbon-poor materials. When wood is sourced from a sustainable forest, it can absorb carbon emissions during the growth of trees. As a result, structures take on the role of carbon sinks, effectively capturing carbon from the atmosphere within the built environment. The Tamedia Office Building32 (fig.3.a) in Zurich, Switzerland, designed by renowned Japanese architect Shigeru Ban, is a recent example of such a strategy. This remarkable structure employs 2000 m3 of prefabricated spruce wood elements with no additional steel reinforcements, resulting in a staggering 70% reduction in CO2 equivalent emissions when compared to comparable office buildings.33 Rammed Earth is another inherently sustainable material that presents diverse advantages. Rammed earth buildings, can be sustainable, cost-effective, and long-lasting, and already provides a solution for inexpensive housing in remote areas.34 The transportation cost of construction materials is significantly reduced when the main bulk component is sourced on-site. Rammed earth walls also have a low ongoing maintenance cost because they do not require painting or other wall treatments while remaining strong and durable. Additionally, their stabilization can be achieved through a combination of cement and construction waste, further improving their environmental impact. In Europe, Martin Rauch and Roger Bolthauser are strong advocates for earthen construction materials. An example of their contribution is the Ricola Herbs Center35 (fig.3.b) in Laufen, Switzerland, designed by Herzog & De Meuron and expertly overseen by Rauch.36 Unfortunately, because earthen walls are extremely vulnerable to seismic shaking due to their weight, gradual deterioration over time, and lack of structural cohesion between components,37, the project ended up being realized with a reinforced concrete structure infilled with rammed earth.

fig.4

a. NEST HiLo roof construction prototype, BRG

- ETHZ b. Tabacco Fabric slab system, Pier

Luigi Nervi. Photo: Marcus Bredt

fig.4

a. NEST HiLo roof construction prototype, BRG

- ETHZ b. Tabacco Fabric slab system, Pier

Luigi Nervi. Photo: Marcus Bredt

Secondly, structural optimizations aim to reduce the required quantity of material while retaining structural properties in a given set of boundary conditions. Drawing on the works of master builders such as Félix Candela, Eladio Dieste, Robert Maillard, and Heinz Isler38, we can trace the historical roots of efficient, economical, and elegant construction methods. Despite budgetary, material, and labor constraints, these pioneers achieved remarkable breakthroughs and pioneered novel structural systems. A prime example is Pier Luigi Nervi’s”39 creative collection of solutions that emerged out of resource limitations and governmental restrictions on steel-reinforced concrete in Italy during and after World War II. This scarcity ultimately led to remarkable advances in the effectiveness of materials and structures. More recently, The Block Research Group (BRG) at ETH Zurich, following the principle of “strength through geometry”40 designed an array of research projects aiming at reducing the amount of material needed by inserting material only where it is needed. By following the flow of forces for all loading instances, efficient structural forms, such as shells or vaults, can greatly minimize the required structural volume. Particularly, the use of funicular, meaning compression-only, configurations can, even with reduced structural sections, also significantly reduce stress concentrations because of their capacity to distribute the load across their section uniformly, further enabling the use of weaker and therefore more sustainable materials.41 The designer can typically separate compression and tension or selectively discretize the structure to manage the structural behavior thanks to structural geometry’s improved understanding of force-flow. The research group’s work culminated in the realization and the NEST-HiLo floor realized in late 2015 in Dübendorf, Switzerland. The suggested solution is modeled after existing tile vaulting examples, which are strengthened by diaphragms, also called spandrel walls. High-performance concrete was used to implement and build this structural system, which has an unprecedented vault and rib thickness of just 2 cm while yet being able to handle asymmetrical stress. Comparing this floor system to conventional 25–30 cm thick concrete floor slabs used in framed buildings, it can save more than 70% of the weight.42

Thirdly, strategies of reuse, ranging from recycled aggregates to structural parts to entire buildings, offer alternative and complementary methods to build sustainably. These methods are predicated on the assumption that demolition processes will undergo drastic changes as demolition sites are currently characterized by broken, crushed, shredded, overturned and piled-up materials that are ultimately disposed of. See chapter I.4 This is a wasteful fate for construction products that were once protected by the building that housed them. Before the industrial revolution, the reuse of components was an integral part of the art of building. In light of the current energy and material scarcity See chapter I.2, we must re-examine traditional practices of Circularity as it is the pathway that holds the most potential for a sustainable future.43

b. Circular Building Economy

“Nothing is created, nothing is lost, everything is transformed” attributed to Lavoisier44 is a principle that was already understood in ancient Greece. In Fragments and Testimonia45 the greek philosopher Anaxagoras makes a similar statement, noting that “Nothing is born or perishes, but already existing things combine and then separate again”. Nowadays, strategies to implement a circular industrial economy are largely theorized in the form of keyworded steps in an array of R-worded concepts in order of priority ranging from the ‘3Rs’in Reduce Reuse Recycle through the more specific ’9Rs’46(shown below) to the exhaustive collection of ‘Rs’ in Moving towards a Circular Economy: More than Just 3Rs!47

- refuse, i.e. prevent the use of raw materials

- reduce the use of raw materials

- reuse, i.e. employ second-hand or shared products

- repair and maintain

- refurbish

- remanufacture, i.e. create new products from (parts of) old products

- repurpose

- recycle, i.e. reprocess the material through mechanical or chemical transformations

- recover energy

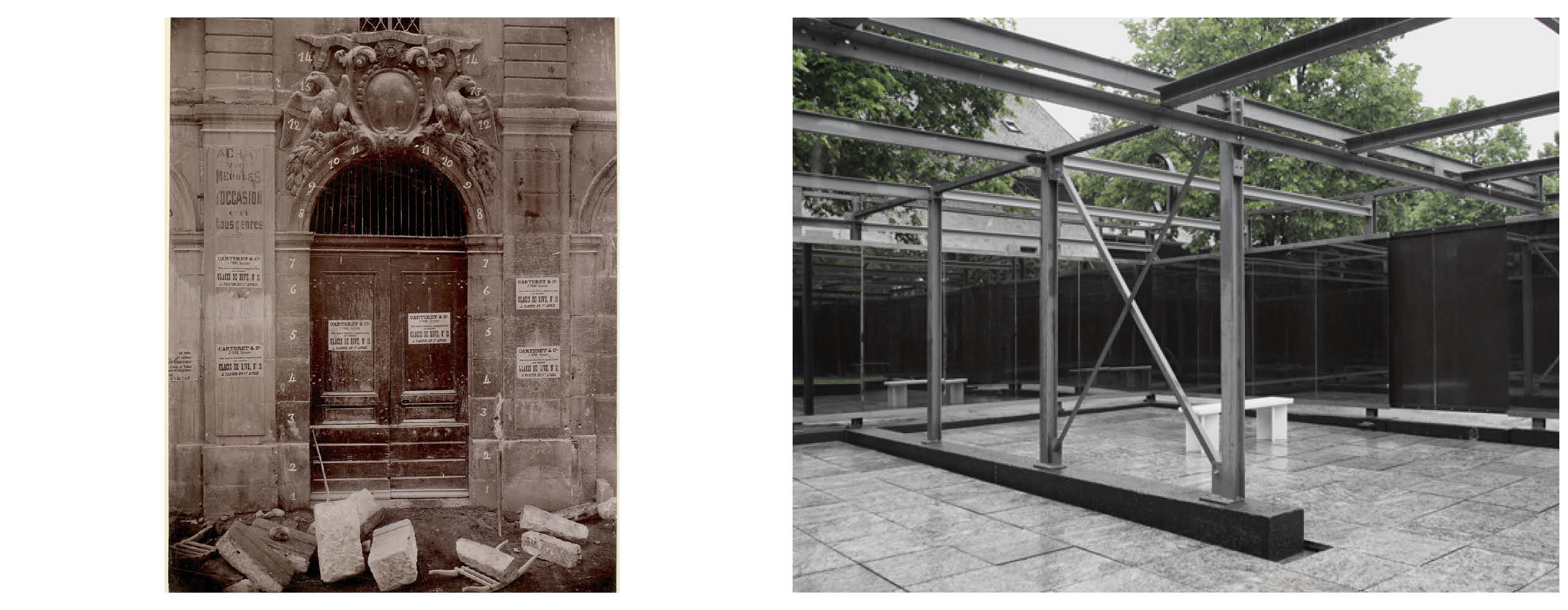

fig.5

a.Démolition du grenier de Rive, Genève (1898)

Bibliothèque de Genève

b. Cabanon

Art Pavilion, EAST ‐ EPFL

fig.5

a.Démolition du grenier de Rive, Genève (1898)

Bibliothèque de Genève

b. Cabanon

Art Pavilion, EAST ‐ EPFL

In the construction sector, circularity proposes a new end of life for building parts. In this case, the term “Reuse” defines the careful removal of components from a construction that has become obsolete, and the extension of their life span in another. A circular approach that seeks to enhance the value of the existing and take care of it in the long term and aims to maintain the manufactured capital over time, thereby simultaneously contributing to climate protection and the development of human capital. By delaying the end of life of existing products, reuse allows for the decoupling of building obsolescence and the production of waste, thereby reducing it. Similarly to the generalistic ways described above, building-specific circular methods are also defined by multiple steps in order of priority. The circular approach will first question the need for the new spaces requested. It will favor the prolonged use of existing buildings through their good maintenance and the intensification of uses within them. Only when transformation, demolition or construction is deemed unavoidable, the circular project will support the re-use of components, extracting them from the “donor” buildings and inserting them into the “recipient” buildings. If reuse is not meaningful, the rejected materials will be recycled, in new components through an energy-intensive transformation process, or thermally recovered or buried. Stock-Constrained Design is a revolutionary transformation of the architect’s role, transitioning from an upstream pre-production role to a downstream post-production one. Rather than being outside of the reuse cycle, architects are now integral to it from the earliest design stages. By mining disassembled buildings for reusable materials, architects can construct new structures from existing components.48 The NEST Urban Mining and Recycling (UMAR) Unit has made a compelling case for constructing with separable materials that are completely reusable, recyclable, or compostable.49 The concept of circularity is thus at the heart of this approach: utilized materials are not consumed and then discarded, but rather borrowed from their technical or biological cycle for a certain period before being returned to these material cycles. This process is often dealt with on a case-by-case basis and at a local project scale. Steel linear elements, such as bars, beams, and cables, are particularly suitable due to their ability to be connected and disconnected reversibly. The “Cabanon Project” in Lausanne, Switzerland (fig.5.b) is a prime example of this approach, as it made use of a part from the International Olympic Committee (IOC) headquarters that was being dismantled.50 51 This locally-focused and specific approach has several advantages, such as optimizing transport and assembly, as well as creating architectural and historical resonance with the surrounding environment. However, this method’s ability to scale is questionable. Each new project would require a fitting existing building to be dismantled locally, which may be a rare occurrence and cause prohibitive friction in the design and building processes.

The K.118 project52 (fig.6) by Baubüro in Situ is an exemplary demonstration of how to approach more complex forms and programs. Located on an old storage site in Winterthur, the architects sought to use only existing elements from demolition projects, thus reversing the traditional planning process. The selection of components was determined by measuring, inventorying, and cataloging, requiring the most precise information to reinstate a component. The project sourced its components from a regional scale, spanning the entirety of Switzerland. Steel girders from the Coop distribution center on the Lysbüchel site in Basel were used to construct the structure, while external staircases from the former Orion office building in Zurich enabled circulation. Aluminum-insulated windows and a red façade sheet from Winterthur and Zurich were used as cladding.53 As the physical parts were discovered and modeled into the digital 3D BIM model, (fig.6.b) the available materials were not deterministic, and necessary changes were applied to create more specific search definitions for yet-to-be-found projects. By utilizing existing elements from demolition projects, the K.118 project demonstrates how complex forms and programs can be effectively managed.

fig.6

a&b K.118, baubüro in situ. An informed

model provided an efficient and reliable way to monitor the availability

status of each element.

fig.6

a&b K.118, baubüro in situ. An informed

model provided an efficient and reliable way to monitor the availability

status of each element.

Building as Material Banks is an idea that is based on the traditional Reclaimed Material Markets that were widely available before the Second World War. Reuse is not a new concept, but its systematic adoption is becoming increasingly important. A variety of institutions and associations are actively promoting reuse, under various over-arching organizations, such as the FCRBE, which aims to identify, meet, and document the reuse sector in North-Western Europe. This project seeks to highlight the existing supply of materials from reuse in the region, ultimately stimulating demand and encouraging the development of the use of reuse materials sold by the operators in the area. A non-exhaustive list of such platforms in Western Europe includes Rotor DC, Opalis. Salvo. In Switzerland specifically: Cirkla, Matériuum, Salza, Rewinner. The fragmented nature of these organizations hinders the efficient assessment of the available material amplifying the need for a common framework for assessing potentially available material.54 Another such hindrance presents itself in the problem of quality uncertainty. The quality of goods traded in a market can be significantly impacted by the presence of information asymmetry between buyers and sellers or by the unavailability of such information, leading to a heightened risk for the buyer. This was highlighted by economist George Akerlof in his 1970 paper, The Market for Lemons: Quality Uncertainty and the Market Mechanism.55 Akerlof argued that buyers and sellers lack equal access to information, or when this information is simply unavailable, it can lead to a decrease in the quality of goods being exchanged. This can have a detrimental effect on the market, as buyers may be unaware of the true value of the goods they are purchasing, resulting in a lack of trust and confidence that can further erode the quality of goods traded and can eventually lead to market failure. This amplifies the need for a solid information and data exchange framework that can be used to set up material banks and provide the traceability necessary to access the characteristics for a new use.56 The ISO1404057 metric defined as Life Cycle Assessment (LCA) offers a potential remedy as a foundational framework for assessing the traded goods quality. By creating an inventory of pertinent inputs and outputs from a product system, assessing potential environmental impacts, and interpreting the findings of the inventory analysis and impact assessment phases, it is a technique for assessing the environmental aspects and potential impacts associated with a product, according to ISO.58 59 However, the LCA methodology still has certain drawbacks, such as neglecting the effects of building and transportation and using average industry levels for all impacts.60 Nonetheless, several policies have been implemented to encourage the establishment of such organizations. In Europe, several action plans have been issued and are currently in progress, such as the European Green Deal in December 201961 and the EU Action Plan for the Circular Economy in 2020.62 In France, the Environment Code defines reuse as “any operation whereby substances, materials, or products are used for a purpose other than the one for which they were designed.” With this in mind, the French government created a roadmap for developing a 100% circular economy in April 2018, aiming to “turn existing buildings into a bank of future construction materials.”

c. Digital implementation

Recent studies have explored the potential of large-scale digital material banks to store material properties and facilitate the reuse of existing structures.63 An effective material or component bank could streamline the reuse process by managing direct reuse more efficiently,64 through collaboration between element stocks, databases, and a market for reused elements.65 Urban mining and building stock surveys, possibly assisted by photogrammetry and laser scanning, can feed a generalized database and provide designers with a wide range of reusable materials. To implement this system, it is essential to populate the database with information from existing buildings, requiring a large-scale digitization process.66 The case of Singapore, where French company Dassault Systèmes is constructing an expansive, informed, and adaptive 3D model of the city, illustrates how comprehensive digitization of the existing urban stock can be accomplished.67 This database system can operate on a just-in-time basis, helping to avoid storage issues, especially in densely populated areas such as metropolitan cities.68 Building Information Modelling (BIM) is the data form that enables this widespread tapping into existing built stock, as the virtual model provides a unified source of building information. A digital representation of real-world entities, encapsulating their characteristics, in both data and function where data describes the state of the objects while function describes their behaviors under certain conditions.

In 2008, Fujita and Iwata of Kanagawa University explored the possibilities of systemic reuse for steel structures.69 Focusing on the Japanese situation of short-term turnover of the building stock due to the disconnect between land value and building value (Chapter I.4), the retail price of an average Japanese house nulls out 20 to 25 years after construction.70 At that time, before the infancy of BIM and smart technological advances such as photogrammetry, their model already positioned the database at the very center of all reuse flows. Revolving around Design, Storage, Fabrication, Construction, and Demolition, elements were tracked on the database throughout their life cycle. In the article titled “Smart Steel: New Paradigms for the Reuse of Steel Enabled by Digital Tracking and Modeling,” David Ness envisioned a new cohesive system of existing digital technologies to facilitate the disassembly, take back, and reuse of structural steel components.71 On a similar model to the previous paper, the system is completed by RFID tags and he describes how information about the structural components is centralized into a BIM database, allowing for data to describe the state of the object and function to describe its behavior under certain conditions.72

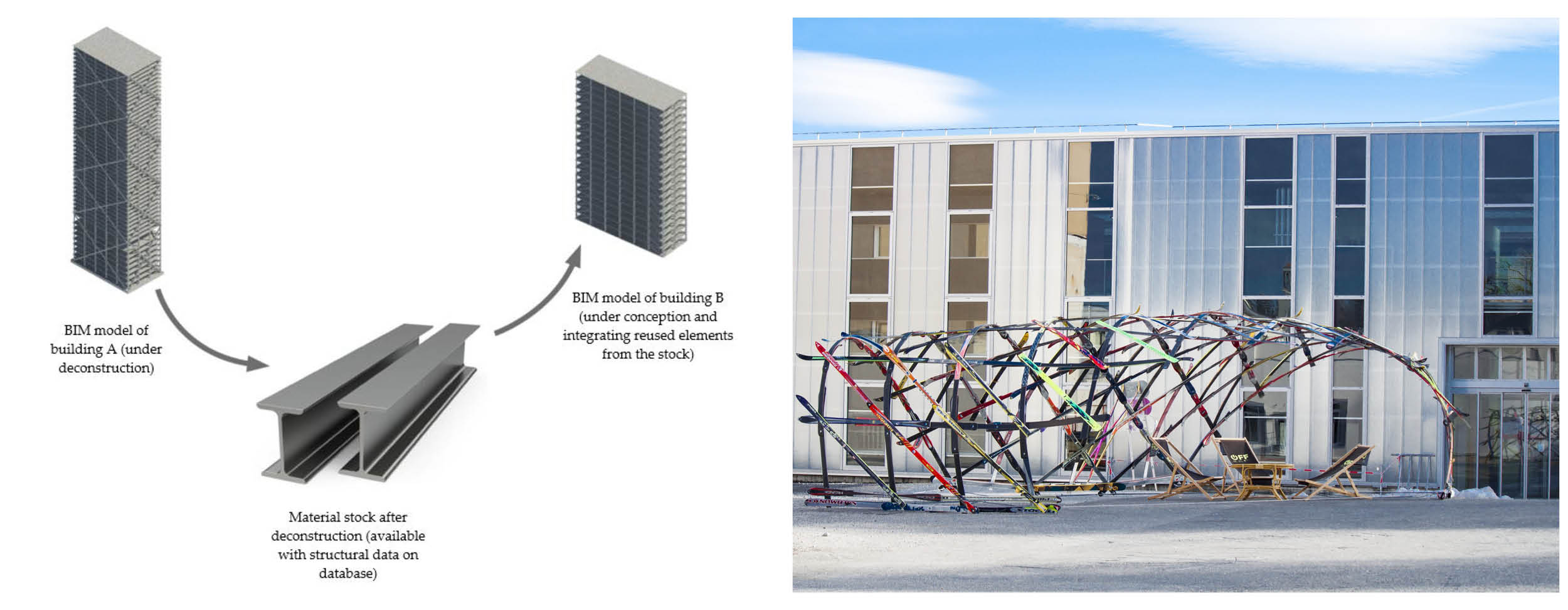

fig.7

a. BIM flow model, Navier Laboratory - École

des Ponts b. Geodesic Gridshell Ski pavilion,

SXL - EPFL

fig.7

a. BIM flow model, Navier Laboratory - École

des Ponts b. Geodesic Gridshell Ski pavilion,

SXL - EPFL

In A BIM-Based Framework and Databank for Reusing Load-Bearing Structural Elements, Ingrid Bertin and the team from the Navier Laboratory, Ponts et Chaussées (ENPC) point out that high-rise buildings are particularly fitting for reuse strategies as they are mainly composed of a large amount of similar, simplified and easily disassembled components assembled in identical spans. Using this analysis they attempt to develop a functional toolchain for using such buildings. The result is a complete BIM-backed framework for the exploitation of elements from a high-rise building in deconstruction. After establishing the necessary parameters for reuse, the information is transferred to a database. Then, the structural and environmental parameters containing the digital mockup are exported to the database. To facilitate this process, a BIM software extension is developed to export the parameters and create a gateway between the model and the database through the BIM software API. To retrieve all the information entered, the extension utilizes a filter based on the existing categories in the BIM software. In practice, the press of a button in the software interface triggers an external command. The connection to the database is made directly in the Design software BIM extension, by writing the parameters to the database. The data is divided into several tables according to the type of element (column, beam, sail, or plate) when writing to the database.73 As a result, algorithmic design progresses from Form Finding to Part Finding.

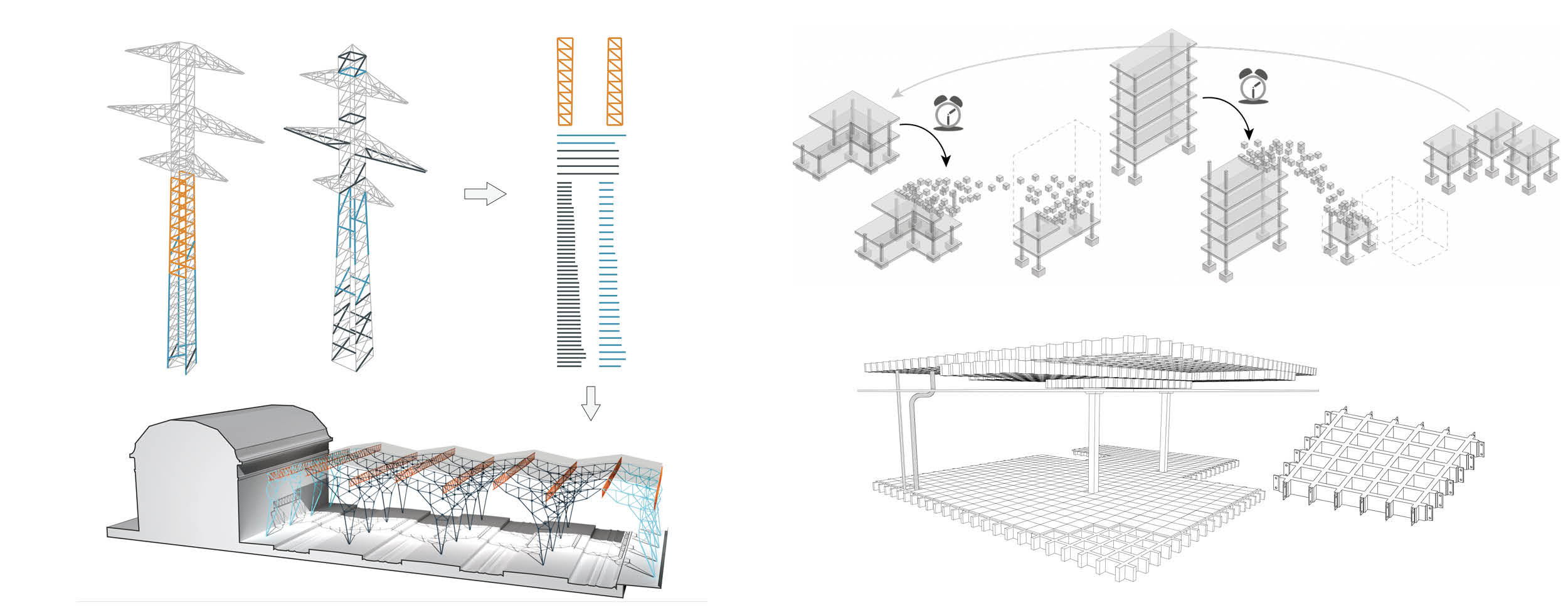

fig.8

a. Roof for Lausanne Railway Station, SXL -

EPFL b. Ready-for-reuse structural systems,

SXL - EPFL

fig.8

a. Roof for Lausanne Railway Station, SXL -

EPFL b. Ready-for-reuse structural systems,

SXL - EPFL

Lastly, the team of the Structural Exploration Laboratory (SXL), at EPFL, has explored precise examples of fully circular projects from recovery to mise en place. It is this research’s laboratory’s main focus to ease and widen the circular use of construction elements. In the following examples, we will examine three of their research paths titled: Optimum Reuse, Waste Upcycling and Design for Deconstruction/Reuse. The path of Optimum Reuse involves developing algorithms to generate structural layouts with the highest possible rate of reuse. Thus, the shape of a structure is determined by its mechanical and geometric characteristics and the availability of elements dictates the arrangement.74 First, a process for constructing structures from both new and recycled materials was created and tested against 100 simulated stocks of reusable components. These were used to create three single-span steel trusses in an innovative way to reduce waste while still creating strong, reliable structures.75 In a second phase, a case study focused on the specific case of soon-to-be deconstructed high-voltage line in Kanton Wallis and to make the most of its readily dismantlable pylon elements76 They tested the ability of the developed algorithm to match the stock of the available elements to a possible structure covering the train station in Lausanne (fig.8.a) while making the most of the given stock of elements. The Waste Upcycling path77 highlights the untapped potential of discarded materials, as outlined in the Smart Living Lab’s publication, Selective Deconstruction/Reversible Construction, commissioned by the Swiss Federal Office for the Environment. It states that waste is an object with no known use, but its economic, technical, or cultural value can be preserved or recovered when a new use is identified.78 This research focuses on repurposing components with structural properties that were not part of their original use, such as skis. In this case, the process is reversed: the system must be constructed using predefined components whose makeup and previous usage are unknown. To ensure the overall stability of the new system, the capacities of each element must be accurately estimated and averaged across the entire structure, while redundant connections provide additional security. As a proof of concept, the team successfully constructed a geodesic gridshell made of reclaimed skis, (fig.7.b) demonstrating the potential of this innovative approach.79 Finally, the upstream approach of Design for Deconstruction and Reuse80 is applicable at the source when the circumstances of construction dictate the need for entirely new components. The goal is then to provide a system of open-ended possibilities for reuse in later projects, following some principles detailed by Corentin Fivet. These principles dictate that the span between two supports should not be limited by the length of beams or slab elements and that the load-bearing capacity of a combination of beams, slabs, or columns is greater than the capacity of the individual components. Thus, regardless of span and element type, floor outlines, ceiling heights, support layouts, vertical service duct positions, and a considerable amount of envelope shape can be adjusted while still maintaining the strength and stiffness of the arrangement. By maximizing the integration between this load-bearing system and other building systems, a building’s architectural language can be altered with minimal to no impact on its load-bearing components.81 This research paper seeks to develop a highly versatile, load-bearing system for 6-story-high office buildings that can be disassembled and reassembled in new spatial configurations up to three times over a 200-year lifespan. The system is a modular structure consisting of interconnected slab modules (fig.8.b) that can be combined into a variety of rectangular floor plan shapes while allowing for a broad range of column layout configurations.82 Such technical solutions promote reuse loops as they enable maximum flexibility to accommodate any potential use and transformation of the building. Building components could flow through the built environment seamlessly from one project to another, providing a sustainable and cost-effective solution.

Conclusions

The existing standard structural design method must be rethought to move towards a circular construction economy, as it creates load-bearing systems that age prematurely and require the destruction of all components. In aiming towards such goals, a combination of effective and existing methods for selective deconstruction and separation of materials, affordable remanufacturing and reclamation certification procedures, and building designs that are better suited to incorporate repurposed parts must be implemented. An efficient end-to-end system for element reuse can also be supported by changes in procurement policies and regulations to encourage reused products, online marketplaces and exchanges powered by Building Information Modeling (BIM) for building wastes and components, Life Cycle Assessment (LCA) product tracking and monitoring similar to material passports. By using parts from previous systems and rearranging them in new structures, this system minimizes resource usage and new production. Reuse methods were more prevalent in the past than they are now, but a revival is imminent. Recent projects have projected that reused projects are 15% less expensive than new construction,83 and this will be accompanied by paradigm shifts in the areas of material sourcing, design approaches, construction details, and footprint analysis. Design professionals are in a unique position to spearhead this shift, especially with the anticipated adoption of carbon taxes on new construction, which could further increase the economic benefits of circular building production.